Building superior products is the reason for our success.

Our mission is to continually improve our products and services to exceed our customers needs; allowing us to prosper as a business and to provide a rewarding work experience for our personnel. Our ultimate goal is to become the best in our business.

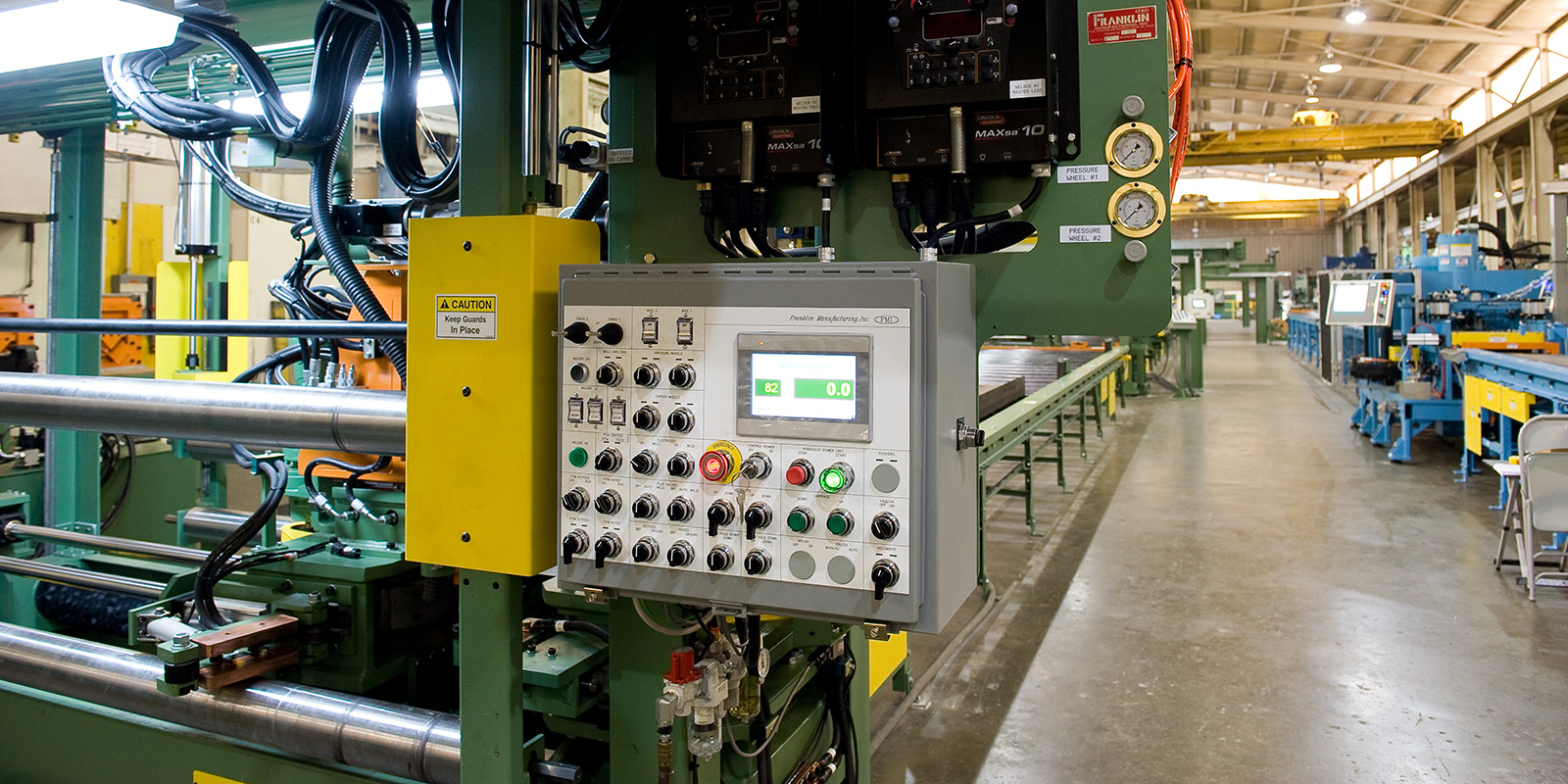

Custom Developed Fabrication Software using Beckhoff PLCs

Franklin Manufacturing, Inc., based in Russellville, Alabama has been a worldwide supplier of high quality CNC fabricating systems for over 24 years. Franklin provides total solutions with its standard product line of CNC fabricating machines. With extensive experience in Steel Fabricating Equipment, Franklin's CNC equipment is used in several markets including Pre-Engineered Steel Buildings, Heavy Structural Fabrication and Joist Fabrication.

Read More

Faster Cycle Times, Quicker Deliveries, and Decreased Labor Costs

Franklin machines include: CNC Flange Lines, CNC Plate Lines, CNC Gantry Retrieval systems with Smart Pickup capability. Cell Designed Systems with positive material flow. Pull-Thru-Welders with material handling, Tack Fixtures, and Web Seam Welders

Read More

Automatic Submerged Twin-Arc Welding System

Designed for fixturing and welding Three (3) piece built-up beams consisting of a web and two (2) flanges. The PTW-72 has a web capacity of 72 inches and flange capacities of 20” wide x 1" thick. A complete PTW-72 fabricating cell can be up to 300 ft. long. The system consists of a web loading gantry, web seam station, tack station unit, 4020 CNC Flange Loading Gantry and PTW-72 Pull Thru Welder with CNC Controls.

Read More

8 Models with 30 - 275 Capacity

These versatile presses are primarily used for piercing the flange sections of beams, angle, channel, and bar.

Franklin uses high quality industry standard tooling in all our presses. Standard tooling shapes are round, square, rectangular, and slotted. Shaped punches and dies are keyed to facilitate punch to die alignment. Flats are used unless other desired configuration is specified when ordering shaped dies.

Shears & Coper Notchers

Available in standard and specialized models, the Franklin Shears & Notchers feature high quality hydraulics, unit constructed manifolds to eliminate piping, adjustable pressure relief, and more.

Special shearing dies can be designed and quoted based on the required application. Frame is totally machined, keyed, and heavily constructed for long life and dependability for many years to come.

Automated Smart Technology

The loading system is designed to accommodate angle iron stock 20, 40, and 60 foot standard lengths; and flat bar stock of 20 foot standard lengths.

All Franklin fabricating systems are available with optional CNC gantry loading (or unloading) and support software with smart pickup capabilities and servo controlled positioning. Models with length capacities of 20, 40, and 60 foot lengths are available.