Is a Dedicated Plate/Detail Line for producing connection plates and base plates. The material is moved and positioned by a Servo Carriage and attached to the trail end of the bar by a Hydraulic Gripper.

- Jaw type gripper with harden teeth

- Replacement upper/lower jaws

- Self contained Hydraulic Unit mounted on the Carriage

- Rigid tube arm weldment

- Servo Carriage running on a Precession 8” x 1.250 Track

- Extremely accurate scale type feedback for X-axis location

- Hydraulic Gripper attaches directly to Trail end of the bar.

- Catrac Cable Carrier for Electrical and Airlines.

Franklin Shear

Franklin Shear

- 425 tons of shearing capacity.

- 1 ¼” x 20” capacity.

- Shear Tooling 5/8” per foot fixed rake

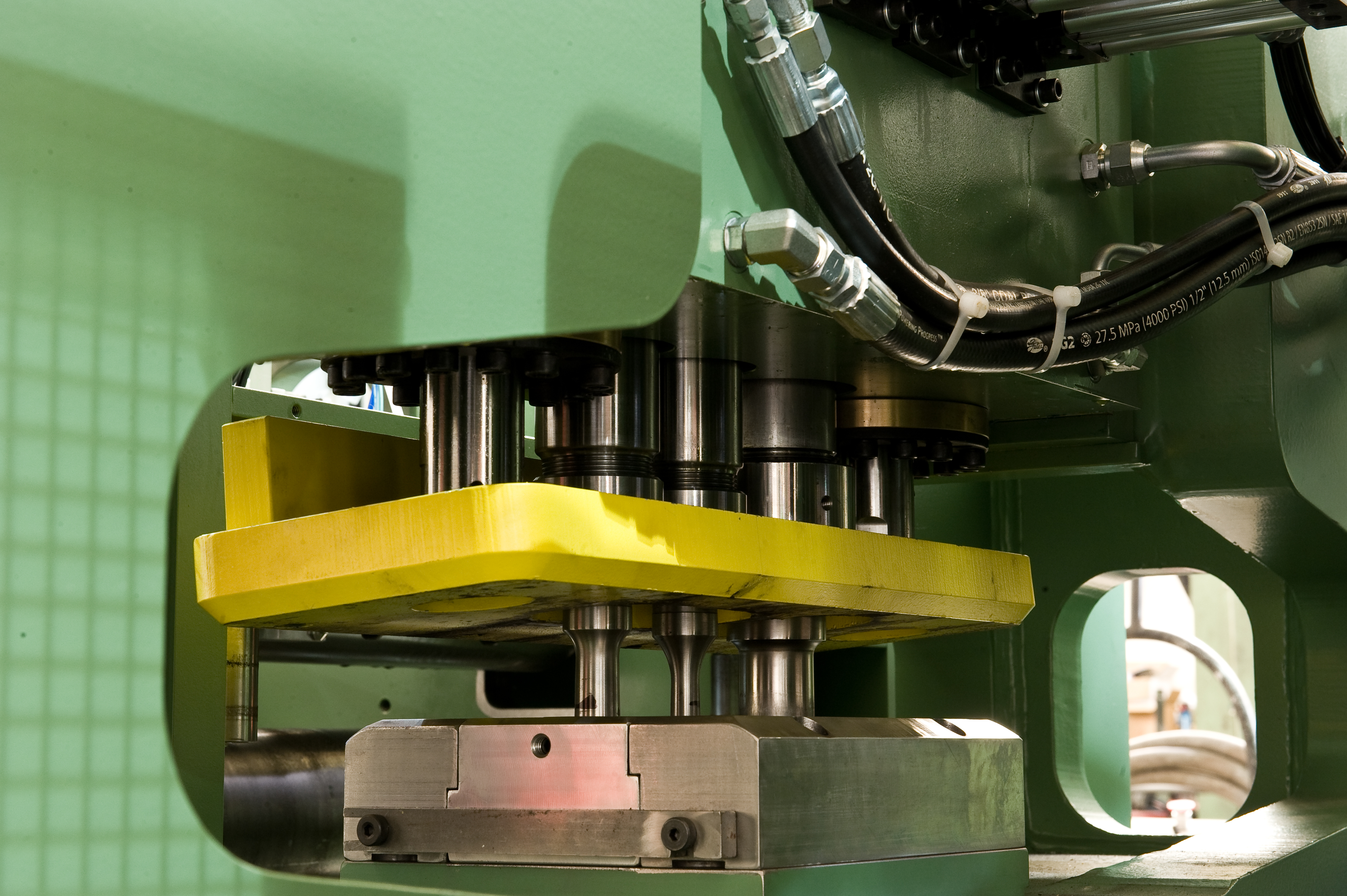

Triple-Gag Tooling

Triple-Gag Tooling

- Three (3) Harden Punch Stems with Air gags

- Each Station can punch individually or pair punch at 3” and 3.5” gauge

- Maximum hole diameter of 2”

- Easy slide out lower die blocks

- Unloads Plates less than 60" long.

- Dual magnets

- Automatic sequence