Franklin Model PF196x425RM is a 20" CNC combination plate/flange line with infinite variable gauge capable of locating holes at any location across the flange or plate. The PF196x425 Equipped with a Model 5425 (425 ton) shear, has a maximum capacity of 20” wide x 1 ¼” thick plate. The 196-ton triple gag tooling contains three (3) tools that can be individually selected thru the CNC program. Punching capacities up to 2 inches in diameter and quick-change tooling provide quick change over for plate fabrication. The flange/plate material is conveyed and measured with a multi-pinch roll drive system. The press assembly is positioned at 1500 IPM by a Hi-Performance Hydraulic servo system.

Franklin BP130X12 CNC Flange/Plate Line with Pinch Roll Feed is a high production combination machine for both plate and flange fabrication.

- 130 ton punch

- Windows based CNC control

- 280 ton shear

- Line speeds up to 225 ft./min

- 12” x 1” bar capacity

Triple-gag tooling (3 tools)

- Three (3) Harden Punch Stems with Air gags

- Each Station can punch individually providing Three (3) punch tool sizes

- Maximum hole diameter of 1.5”

- Easy slide out lower die blocks

Franklin BP5196x20 CNC Plate/Flange Line

Franklin BP5196x20 CNC Plate/Flange Line

Franklin BP5196x20 CNC Plate/Flange Line is a high production combination machine for both plate and flange fabrication.

- 196 ton punch

- Windows based CNC control

- 425 ton shear

- Line speeds up to 225 ft./min

- 20” x 1.250” bar capacity

Triple-gag tooling (3 tools)

Triple-gag tooling (3 tools)

- Three (3) Harden Punch Stems with Air gags

- Each Station can punch individually or pair punch at 3” and 3.5” gauge

- Maximum hole diameter of 2”

- Easy slide out lower die blocks

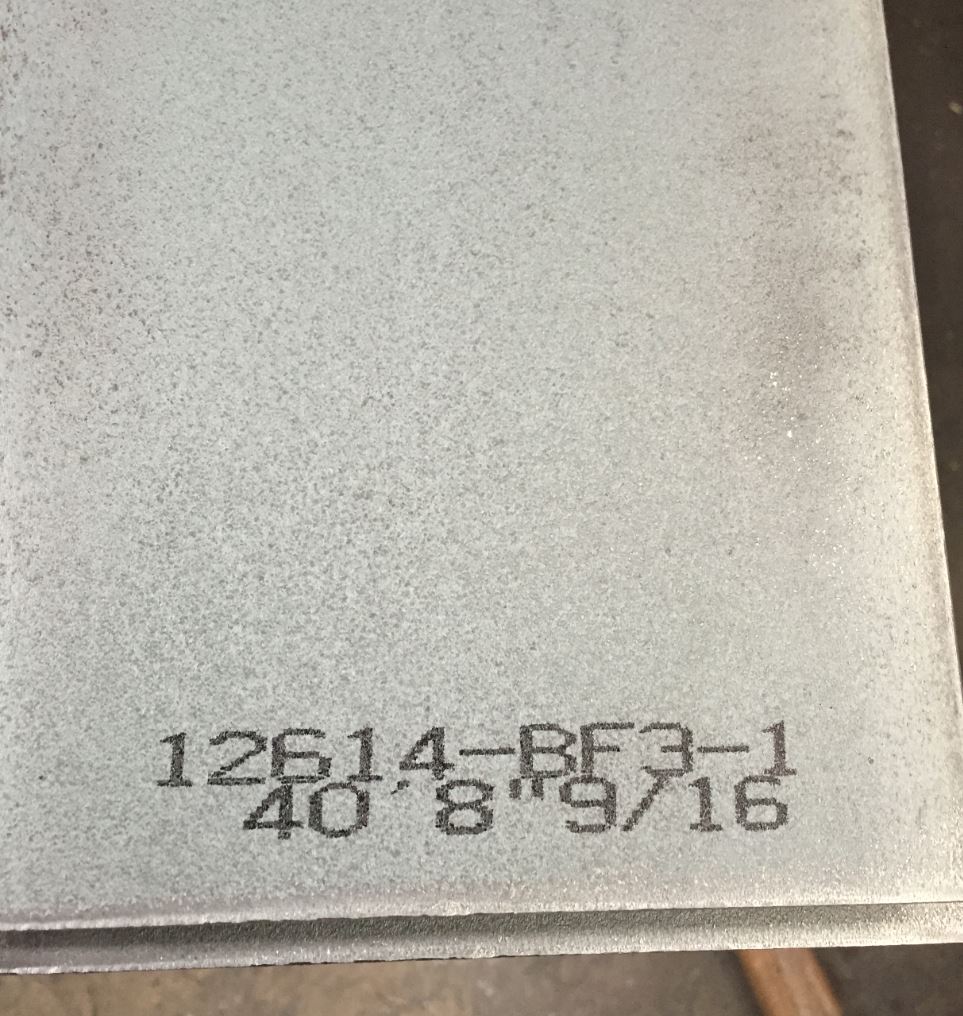

Provides CNC control of part identification for flanges and plates. The identification mark is automatically defaulted from the CNC part file.

The Franklin Powered flange stacking system provides an efficient handling of hi-volume flange production. Each flange stack can be power transferred directly into the TS-72 Tack Station gantry pickup zone.

The Franklin Powered flange stacking system provides an efficient handling of hi-volume flange production. Each flange stack can be power transferred directly into the TS-72 Tack Station gantry pickup zone.

CNC OPERATOR INTERFACE

CNC OPERATOR INTERFACE

- Dual USB Parts

- Integrated Touch Screen

- IP65 Rated Enclosure

- Compact Flash Memory

- Integrated E-Stop

- Intel Microprocessor

- Dual Ethernet Ports

- Integrated Keyboard

- 0-55 C Temperature Rating

- Integrated System Key Switch

- Pedestal Mounted

- Ram Memory

- 15” Color Monitor

- Integrated Function Keys

- Totally Solid-State

Franklin “4050 CNC”

Franklin “4050 CNC”

Gantry loading system provides a full auto-loading system for flange and plate production. All material bins are stored in the CNC control and are fully adjustable.

- Power Wave AC/DC 1000 amp Power Wave

- MAX-sa 10 controls

- Flux Recovery

- Plasma Bevel and Pre-cut for Step Flanges

- Smoke Recovery and dross pan